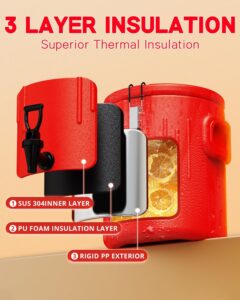

”Insulated – perfect fermenting vessel for a “mash.”

Objective

The objective is to create a mixture where the yeast can get to sugars to convert them into alcohol. Even if you use sugar as an ingredient you must heat it to break down the cellulose pulp to make the sugars yeast-friendly.

Enzymes

The sugars in grains like corn and wheat must be broken down with a malt barley. You could instead use a processed amalyse solution, 1 teaspoon per 5 gallons.

Barley is just another grain, but malted barley is different! Malted barley has already started to germinate. At that stage the barley turns mostly to enzymes. These enzymes at on the grain to separate the sugars from the pulp. The germinated barley is only allowed to germinate a little bit, then it is killed by excessive heat from an oven at a certain temperature. This is done such that the enzymes still remain and can be activated with some heated water. These enzymes work on the sugars in the barley and then they go and activate sugars in other grains present. Other than their own activation, they can activate sugars in other mixed grain at about 4 times the amount that they weigh.

Mixing the Enzyme Barley in before Distilling

Water – Pour in 5 gallons (20 liters) of good quality water.

Grains – Add grains while heating the water to max 150F. After the grains thicken by soaking up all the water, add a little cracked malted barley slowly to liquify the mix. Keep adding the cracked barley slowly until all barley is in. Heating past 165F will kill the enzymes and no conversion will take place!

The temperature should be 145F plus or minus 5 degrees. This temp should be consistent through out the mashing process which is adding the malted barley to the grains to convert the starches to sugar. This mashing period should be finished about an hour to an hour and a half.

Malt – Add 1 gallon (4 kilograms) of cracked malted barley to max 5 gallons liquid.

HEATING MASH

Put mash into a micro mesh hop strainer or a micro spaced nylon netting bag. This is so the mash doesn’t touch the bottom of the pot and scorch producing a burnt taste in the mash that you can’t get out. Filter through a strainer if no bag used

Then raise the heat to 165F max(73C) for several minutes to kill any bacteria before adding any malted barley.

Cool the temperature to 150F then add the malted barley. Sustain the temperature at 150 F (65C) for one to one and a half hours. Stir constantly at first, then every ten minutes. Most of the converting to sugars by the enzymes occurs within 20 to 30 minutes.

Pour the mash batch through a strainer to separate out the pulp particles.

Use iodine drops on a potato to see a starch reaction. The result will be a very black color. Use this same test to two teaspoons of the finished liquid mash to show no more starch left in the mash. After finishing the mashing process there should be no black color from the test. Stir or shake around the small test amount to see the dark color dissapate.

No Heating Method

An alternate method to heating the mash is to fill with boiling water into a large insulated jug. Then add the cracked corn or other grains (not the malted barley yet). This will bring down the temperature to around 180F. Stir around the grains and cool or wait until the temperature drops to 150. Then introduce the barley stiring it. The insulated jug will maintain the 145F temperature through out the hour long mash stiring process. Stir constantly at first, then every ten minutes. If you don’t have an insulated jug, insulate your pot with reflective bubble insulation. Double it up.

Sparging (rinsing)

The mash will have soaked up a lot of water. A 5 gallon water starting amount will be down to 3 gallons since the other 2 gallons will be soaked up into the mash grains.

Put the grains in a dense mesh netting above the pot and rinse it with clean hot water. This gets out the coverted sugars still inside the grain mash. The total liquids will increase back up to 5 gallons. You can take the soaked grains and sparge into a separate pot with hot water to rinse the malt enzymes that are still in the mash strainer comtainer and add that liquid to the previously heated mash liquid.The left over pulp is thrown away. You could save it and make a sour mash in a next batch.

Best to scoop out a large amount and put it into a fine net bag. Sparge. Then hand squeeze out the pulp. Repeat until all pulp is gone.

Pour into fermenting vessel.

Cool mash down the produced liquid to 85 F max, preferably 75F. Use ice in a freezer bag to speed up the cooling.

Check gravity (1.10+-) potential 17% ABV