Definition

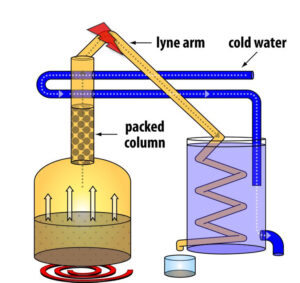

Called a forced reflux still. Unlike pot stills, reflux stills are designed to create higher proof with little to no flavor alcohol. Inside the still is a column that allows the reflux of liquid to help condense the rising vapor and increase the efficiency of distilling, thus increasing purity. The taller the column and the more reflux liquid will occur and the more neutral the alcohol will be.

How It Works

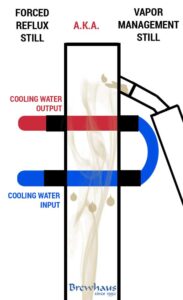

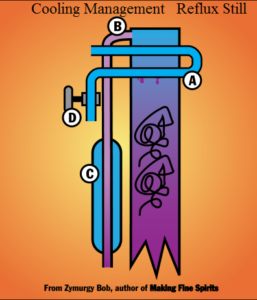

Forced Reflux Still

Cooling tube design. Cold water is run inside tube on the inside the column so when the steam vapor comes in contact with these tubes it instantly condenses and falls back down and vaporizes again from the rising heated steam. The cool temperature radiates out from the tubes. Only the lightest vapors get by the cooling tubes.

The speed of the distillation is determined by the cool temperature of the cooling tubes. Most of the water and mash particles fall back down. The lighter alcohol vapors get by the cooling tubes and then go to the main condenser to be liquefied at a high alcohol content.

The columns cooled at the top from outside the column are very ineffective and only a marketing ploy.

Task

The difference here is the need to really equilibrate the column at the start of the run, so that the methanol gets to accumulate at the top of the column,

and to get all the packing in the column up to its equilibrium temperature so that it will work its best. This can take from 1-4 hours.

It works at its best when it requires quite a high reflux ratio – returning 8-12 times back to the column.

Cooling tube design

Cold water is run inside tube on the inside the column so when the steam vapor comes in contact with these tubes it instantly condenses and falls back down and vaporizes again from the rising heated steam. The cool temperature radiates out from the tubes. Only the lightest vapors get by the cooling tubes.

The speed of the distillation is determined by the cool temperature of the cooling tubes. Most of the water and mash particles fall back down. The lighter alcohol vapors get by the cooling tubes and then go to the main condenser to be liquefied at a high alcohol content.

With the internal reflux design, you still control your distillation with a needle valve, which controls the speed at which you collect your distillate. Even the actual design inside of the column is altered very little.

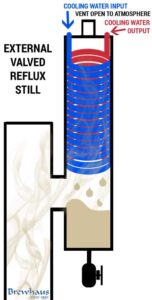

External Valve Reflux

The column rises from the boiler with either a 90 degree elbow, or more commonly a tee fitting, at the top of the column. A thermometer is installed at the top to read the temperature of the vapor at the head (top) of the column. The vapor, having nowhere else to go, travels across the tee fitting to the reflux head.

The vapor will come into contact with the coil, and the refluxing liquid will then drip straight down into the lower portion of the tee fitting.

The needle valve allows the user to control the speed at which distillate is collected, and in doing so also control how much of the refluxing liquid is returned to the column. Leaving the valve open entirely collects all the distillate, simply column still,