Definition

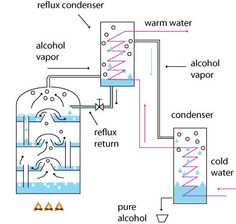

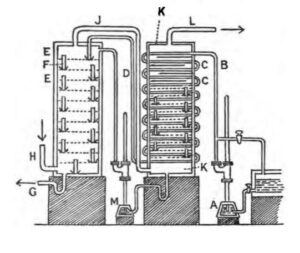

A fractionating distillation column is the best solution for making strong alcohols. Such a column can produce pure 95% alcohol in one operation. A fractionating column contains a number of plates or trays ( each plate spans a portion or fraction of a column). These plates function as containers where separation of alcohol occurs. Each container functions like a separate pot still. These container plates are stacked on top of each other refining the liquid finer than the plate below it. So the top plate will have the most alcohol in the liquid with only a small portion of water and other mash flavor particles.

Reflux still is like a lot of pot stills assembled together that’s why it can make multiple distillation in a single run. This is how vodka and rum are distilled and then just diluted to proof safe for human consumption.

Forced Reflux Still

Cooling tube design. Cold water is run inside tube on the inside the column so when the steam vapor comes in contact with these tubes it instantly condenses and falls back down and vaporizes again from the rising heated steam. The cool temperature radiates out from the tubes. Only the lightest vapors get by the cooling tubes.

The speed of the distillation is determined by the cool temperature of the cooling tubes. Most of the water and mash particles fall back down. The lighter alcohol vapors get by the cooling tubes and then go to the main condenser to be liquefied at a high alcohol content.

The columns cooled at the top from outside the column are very ineffective and only a marketing ploy.

a better, sleeker appearance, but this does not substantially alter the performance or basic operation of the column.

With the internal reflux design, you still control your distillation with a needle valve, which controls the speed at which you collect your distillate. Even the actual design inside of the column is altered very little

just move the reflux head of an external reflux still to the top of the column to create the internal valved reflux still.

it has the same benefits and drawbacks of the external valved reflux column.

the external reflux and internal reflux designs known as liquid management stills.

External Valved Reflux

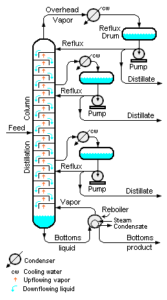

The forced reflux takes place outside the main column.

reflux takes place outside of the main column body.

The column rises from the boiler with either a 90 degree elbow, or more commonly a tee fitting, at the top of the column. A thermometer is installed at the top to read the temperature of the vapor at the head (top) of the column. The vapor, having nowhere else to go, travels across the tee fitting to the reflux head.

The vapor will come into contact with the coil, and the refluxing liquid will then drip straight down into the lower portion of the tee fitting.

The needle valve allows the user to control the speed at which distillate is collected, and in doing so also control how much of the refluxing liquid is returned to the column. Leaving the valve open entirely collects all the distillate, simply column still,

The primary issue with such a design is that the lower portion of the tee fitting (where the condensate drips into) has a reservoir that holds the distillate to be collected. All rising vapor that reaches the top of the column will be condensed when it reaches the cooling coil, and that condensate will then drip into the reservoir. This means that even the vapor requiring further purification will be mixed with the other distillate in the reservoir, reducing the purity of the final distillate to at least some degree. This can be remedied by replacing the tee fitting with a 90 degree elbow so that this collection area is eliminated.

General Theory

stabilize temperature in the column, not the pot …

Procedure

Uniform temp in column

Monitor temp at the very bottom of the column and at the very top. a temp gauge in the middle is very helpful to know exactly what is happening

slowly open reflux valve and monitor the temp until it reaches …

What is a “Forced” Column/Reflux Still

Fractioning Still (Flute)

A fractionating distillation column is the best solution for making strong alcohols. Such a column can produce pure 95% alcohol in one operation.

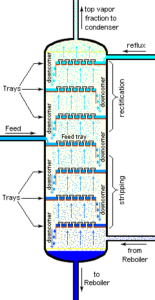

A fractionating column contains a number of plates or trays (each plate spans the area of a tube leaving a fraction of space for the steam to get by, ie holes for steam to raise past the plate). These plates function as containers where separation of alcohol occurs. Each container functions like a separate pot still. These container plates are stacked on top of each other refining the liquid finer than the plate below it. Each plate will distill a fraction of the end product. So the top plate liquid will have the most alcohol with only a small portion of water and other mash flavor particles.

How It Works

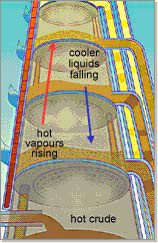

Typically the Fractioning Still set up as two large stacks. One column acting as a distiller … and the other column as a condenser.

More correctly called a forced reflux still. Unlike pot stills, forced reflux stills are designed to create higher proof with little to no flavor from the mash. Inside the still is a fractioning column that allows the reflux of liquid to help condense the rising vapor and increase the efficiency of distilling, thus increasing purity. The taller the column with many plates, the more neutral the alcohol will be coming through the condenser.

Feed tray

each feed tray is like one pot still. It does a mini distillation.

A Forced Reflux still is like a lot of pot stills assembled together that’s why it can make multiple distillation in a single run. This is how vodka is distilled and then just diluted to a proof safe for human consumption.

typically set up as two large stacks

one column acting as a distiller and the other column as a condenser

Dephlegmator – a must have

A dephlegmator is only used in a column reflux still with numerous boiler plates and is a necessary component to make a column reflux still work. It is also called a pre-condenser.

A dephlegmator is a device arranged for the partial condensation of column vapor stream. The vapor stream flows vertically upwards and the dephegmator (a condenser at the top of the column) cools the steam making the heavier vapors condense and run back down under the influence of gravity like a misting rain. The very light vapors [alcohol] rise through the dephlegmator and pass to the external condenser. This separation of the light and heavy vapors is the very definition of reflux.

Uniform Temp in the Column

You must monitor temp at the very bottom of the column, and at the very top with temperature gauges. A temp gauge in the middle is also very helpful to know exactly what is happening.

Heat the pot to 190F.

First method: Run as a pot still. The bottom plate will start to fill up. The the others will follow. When they are all full, the foreshots will start coming out. The Temperature gauge at the top of the column should be at around 170F. Discard the foreshots and start the dephlegmator. Adjust it so that a steady stream comes out of the condenser. Collect the Heads and the Hearts.

Second method: Run the dephlegmator full open and load the column. Balance the column first so no vapors passes through to the condenser. This will insure all the vapors will fall.. Wait until all the plates are full and bubbling. The top plate will load first with the liquid from the plate below it. The column needs to equilibrate at the start of the run, so that the methanol gets to accumulate at the top of the column, and to get all the plates and to the column top to an equilibrium temperature so that it will work at its best. Then reduce the water stream to the dephegmator. A balanced column means the temperature is the same in all the plates. By releasing vapor the temperature is also released and the column starts to become unbalanced. To keep the column balanced the heat coming into the bottom of the column must equal the heat being lost at the top of the column. The temperature gauge at the top of the column should read 170F. The foreshots will come out next. Discard them, and collect the heads and hearts.

Working at its best requires quite a high reflux ratio – returning liquid 8-12 times back to the column .

The pot temperature will rise slightly as the alcohol is evaporated off. As the alcohol stops coming out the pot should be at around 198F.

When to stop??? When you have collected around 20% of your original gallons of pot mash or wash, then you have to pay close attention. The bottom bubble plate will have almost no activity yet the top bubble plate will still be active.

You will detect the signs slightly at first. Check the taste, smell, feel in your hands. When you are sure the tails are starting, shut everything down right away. Don’t try to collect the last of the hearts and some of the tails. That is the start of the high temperature fusil oils.

Cleaning Copper Plates

After a run the copper plates get tarnish on them of copper sulfate. You do not want this on any copper at the beginning of your next run. This copper surface needs to be cleaned after every run.

Clean them with 5-5-1 solution. 500 ML of water, 50 ml hydrogen peroxide (3%), one ounce in weight of citric acid. Soak the plates for 45 minutes to 1 hour. The plates will come out sparkling clean. See the section on cleaning copper under the post-distilling section.